The big accomplishment this week was finishing the ray tracing software, though finish is perhaps the not the right word. All the code needed for simulating a .stl 3D model with transparency, light absorption, reflection and diffusion is done and it passes all the software tests I could think of coding in. However, I fully expect that there is some problem deep inside, meaning the results are not physically accurate. So the next stage is to find that error(s). I designed a 3d printable test chamber that I can easily model the light flux in using my code, but also build and measure the light flux in using my PAR (Photosynthetically Active Radiation) meters. The first test will be a diffuse emitter and a black absorbing chamber, keeping things simple. Then I can add other complications and narrow in on any simulation errors.

I also worked on inflatable greenhouse plastic glazings. In a typical greenhouse there are two layers of plastic and a blower inflates the space between to keep them apart and provide some insulation. The blowers typically used for these applications seem way overkill. The question is, is that because typical applications leak a lot of air? Or because they want to fill it up fast after power failure? I got a blower and worked on making a test section that was tightly sealed on the edges. I also designed a water manometer to measure the pressure inside. The few sources I could find on that say about 10 mmH2O is enough. The leaking is the key I think, if there are no leaks, the air should be still, which will make it a better insulator.

The double plastic glazing system is pretty well universal on small farms, but it’s not very effective insulation. Even with the best plastics R-1 to R-2 is typical. One question I’d like to answer with the ray tracer is if adding clear plastic gussets in between the greenhouse films would decrease light. I think not, as long as the gussets are normal to the plane of the greenhouse films. This would allow for sectioning off the air space and improving R-value by stopping natural convection.

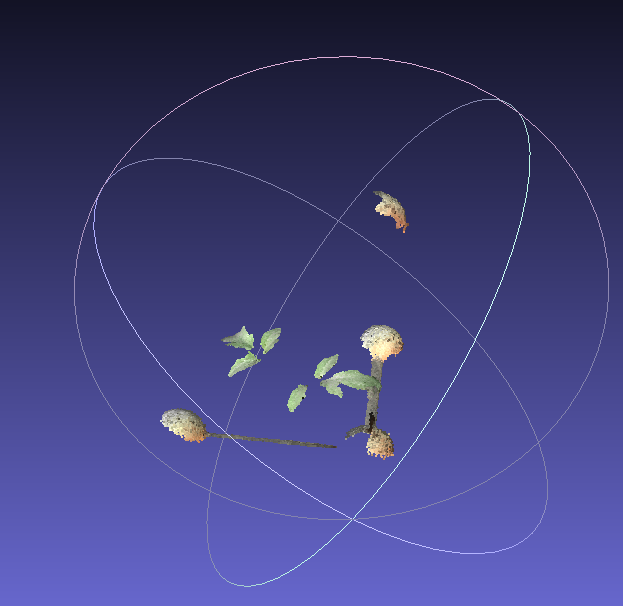

I also scanned my tomato plant seedlings to calculate the leaf area and orientation for ray tracing. This seemed to work ok, though the leaves were still small and some of the tiny ones didn’t show up in the scans. I didn’t have any trouble with the plants moving during the scan, but now I need to get a process to turn them into .stl files from .ply and remove the markers that I put in the scan to get orientation. I scanned each plant twice so I’ll have an estimate of my reproducability.