This week was again spent trying to get the ray tracer validated, and I think I am victorious, but that’s always subject to further revisions! Well, not all ray tracer stuff. I worked on the corporate taxes for SR&ED which is a super program for research companies like Sun Aquasystems. Any Canadian corporation should check it out.

I also worked on the modelica simulation of the growth chamber. Because the scanning of the plants didn’t work out it’s very difficult to make an accurate judgment of LAI, which means it’s very hard to calculate leaf temperature, which is key. The moral of the story is you should just measure leaf temperature with a thermocouple, which I will do in the next trial. I think I will devote my time to making a good simulation of the test greenhouse, which will then inform what measurements I should take for validation. A major complication that I have is that the greenhouse is relatively shallow so all the thermal radiation calculations need to look at the south wall and the roof and north wall, while vanthoor could consider it as one dimensional towards the roof. I may have to use the ray tracer to calculate view factors.

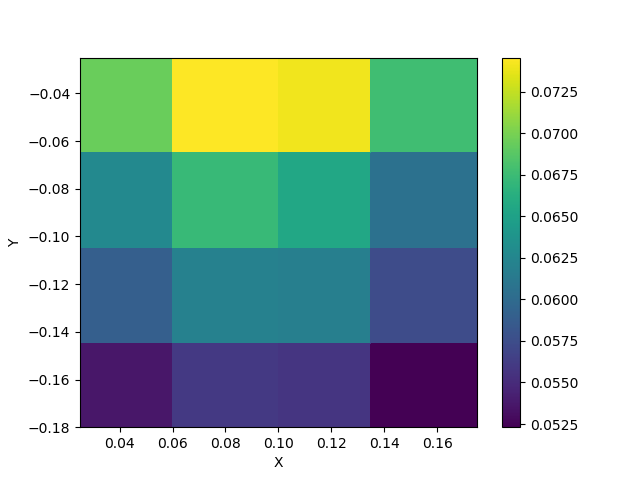

For the ray tracer I tried validating it outside with 0,1,2 layers of greenhouse glazing. First I found the sensors did not read the same after rotating 90 degrees, and after testing with a different stand, I think it was a problem with the side shade. So I took that off, accepting that there would be some error from that. I also raised the sensors so that the albedo of the text box should have no effect, and I waited for a cloudy day so I only had to deal with diffuse light, and… finally the measurements seem pretty reasonable. I got 83% transmission of diffuse light through 1 glazing layer and 71% through two layers. If the index of refraction is 1.55, then 83% transmission is exactly correct. 0.83^2 is 0.69, but there is multiple reflection paths so 71% is reasonable.

After much calculating, the rayctracer simulation gave: 0.827 and 0.716. This was done by simulating the sun at 15 different zenith angles and all around the compass rose the summing the results. Note that this is not the same as putting the sun directly overhead and then through a perfectly diffusing sheet. Only took me a day to realized that… Oh well. At any rater, I think that’s pretty conclusive that rayctracer gives valid results, at least for glazing transmission.

I think the next step is to make some small greenhouse panels with a PAR sensor in each, and log data for a day, comparing with a solcast-rayctracer simulation. That will give me information about how accurate I can expect the historical simulations to be and perhaps expose any problems in rayctracer. But I haven’t had to correct the tracing code so far so that’s good.